When it comes to motorcycle performance and reliability, one crucial component that often goes unnoticed is the ball bearing cage. As an integral part of the ball bearing assembly, the cage plays a vital role in facilitating smooth rotation and reducing friction between the bearing balls.

In this blog post, we will delve into the science behind ball bearing cage manufacturing for motorcycles, shedding light on how this intricate process contributes to the overall performance of the two-wheeled machines. At Bike Nation, we take pride in our expertise in manufacturing high-quality ball bearing cages specifically designed for motorcycles.

The Role of Ball Bearing Cages: Before we dive into the manufacturing process, let’s understand the role of ball bearing cages in motorcycles. Ball bearings are responsible for reducing rotational friction and supporting axial and radial loads. The ball bearing cage acts as a separator, maintaining an equal spacing between the bearing balls, preventing them from rubbing against each other, and ensuring efficient load distribution. This arrangement allows for smoother rotation, reduces wear and tear, and ultimately enhances the performance and longevity of motorcycle components.

Design Considerations: Manufacturing ball bearing cages for motorcycles involves careful consideration of various design aspects. At Bike Nation, we employ advanced engineering techniques to develop cages that meet the specific requirements of motorcycle applications. Factors such as load capacity, operating speed, temperature, and environmental conditions play a crucial role in determining the design parameters.

Material Selection: The choice of material for ball bearing cages is critical as it directly impacts their performance and durability. Common materials used include steel, brass, and nylon. Steel cages offer excellent strength and rigidity, making them suitable for high-load applications. Brass cages possess good heat resistance and corrosion resistance, often found in high-speed or high-temperature environments. Nylon cages are lightweight, exhibit low friction, and are ideal for reducing vibration and noise. Each material has its own advantages, and the selection depends on the specific requirements of the motorcycle.

Quality Control: At Bike Nation, we prioritize stringent quality control measures throughout the manufacturing process. The cages undergo meticulous inspections and tests to verify their dimensional accuracy, smooth operation, and overall quality. These quality control protocols ensure that only reliable and high-performance ball bearing cages reach our customers, contributing to the smooth functioning and longevity of their motorcycles.

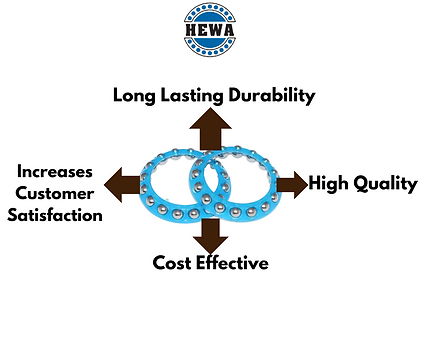

Ball bearing cage manufacturing for motorcycles involves a combination of engineering expertise, precision manufacturing processes, and rigorous quality control measures. The careful selection of materials, coupled with advanced machining techniques, results in ball bearing cages that optimize motorcycle performance, reduce friction, and increase durability.

At Bike Nation, we are committed to providing high-quality ball bearing cages specifically designed for motorcycles, ensuring smoother rides and improved reliability for motorcycle enthusiasts worldwide.